The Company Health and Safety Policy

Dealing with chemicals and operating in sensitive locations, safety is always an absolute priority upon which we never compromise, whether in our production plants or their local environment, in the transportation of our products, or in their use by our customers. Adisseo is committed to an ambitious safety and environmental protection policy.

Our HSE (Health, Safety and Environment) policy is the key to ensure the sustainability of the company and covers our full range of activities. It is based on a continuous improvement commitment, which shapes the policy’s fundamental principles and collective goals.

At Adisseo we endorse the principle upon which there can be no performance for a company if it has accidents in its operations, nor is it conceivable that people should be injured or put their lives at risk in the course of their work.

This is supported by a systematic and in-depth analysis of risks and losses, and the implementation of the best prevention techniques by associating all stakeholders in a commitment to Sustainable Development.

Adisseo’s health and safety policy is based on the following six principles:

- Ensure the health and safety of people through prevention and control of risks, contributing to well-being in the workplace.

- Demonstrate leadership and example.

- Take into account risks related to processes, products and ergonomics in safety risk analysis studies, right from the design stage, in order to guarantee the safety of people and processes in the workplace.

- Help prepare the organization to manage possible emergency situations.

- Reduce risk by investigating incidents and near misses.

- Require subcontractors to manage safety in accordance with this policy.

Safety Performance

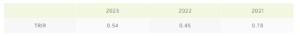

After 2022, during which Adisseo saw its safety performance on target, the situation deteriorated during the first semester of 2023. The good performance of the second semester was not sufficient to meet our yearly target. Actions has been taken to reinforce our policies and HSE networks. A new HSE Executive Council has been set up to make sure that the level of safety culture is raising at the level of expectation of the Group and specific HSE Road maps are carried out on the few places where the situation needs improvement to consider specificity of these few locations.

All our major industrial plants which present our major safety risks, are voluntarily certified ISO45001, as well as our research activities (total of entities representing more than 60% of our employees (> 1500 people).

TRIR: Total Recordable Injuries Rate

10,8

million € Health and safety operational cost in 2022

Road traffic injuries

1.3 million

deaths

50 million

injuries each year

Source: UN Nov.2022